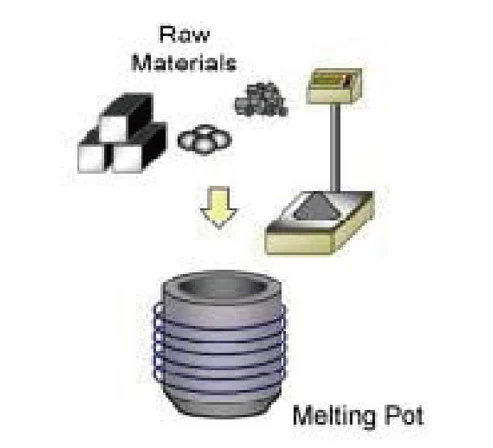

Proportioning

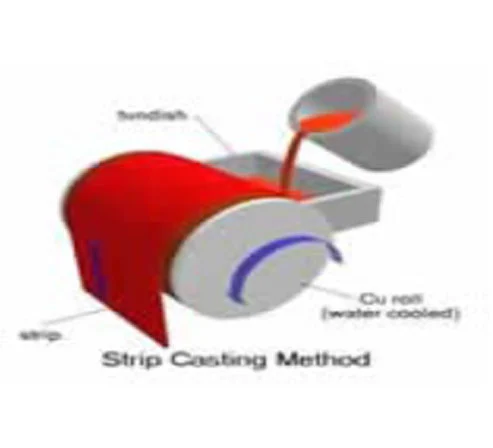

Smelt

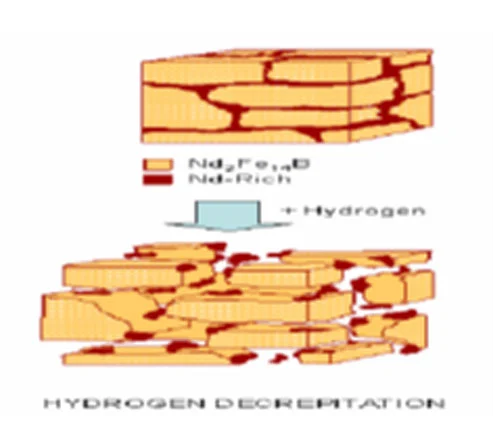

Hydrogen Demolish

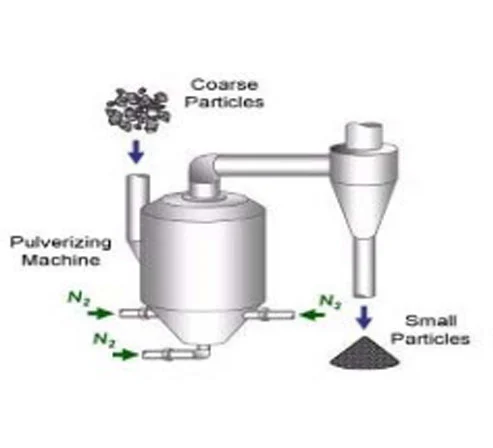

Airflow Mill

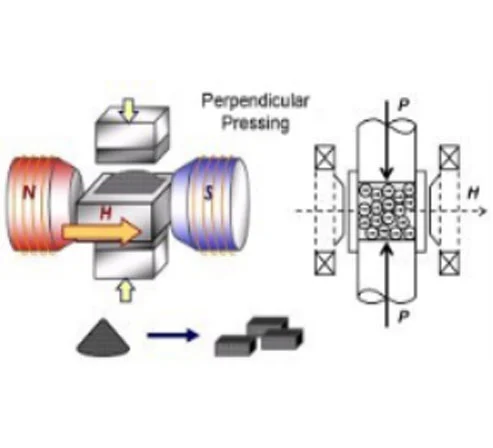

Forming

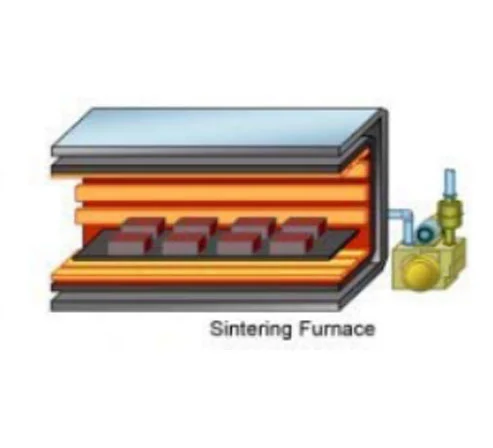

Sintering and Aging

Inspect

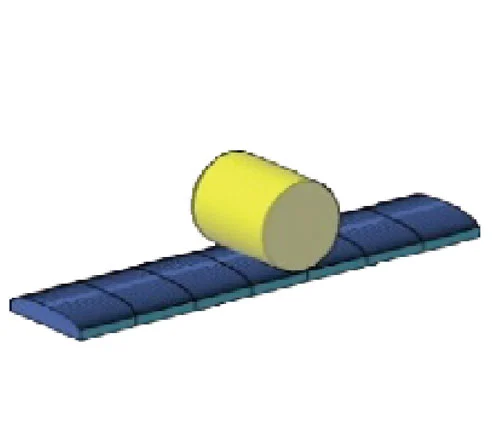

Machining

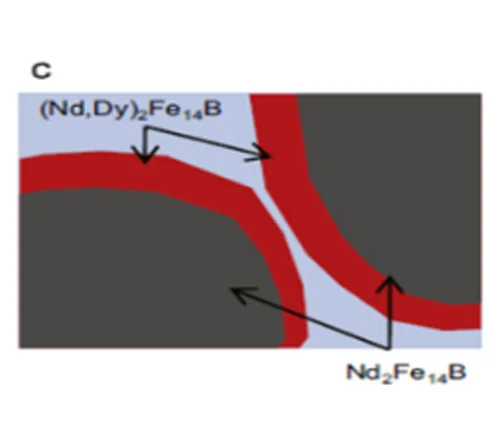

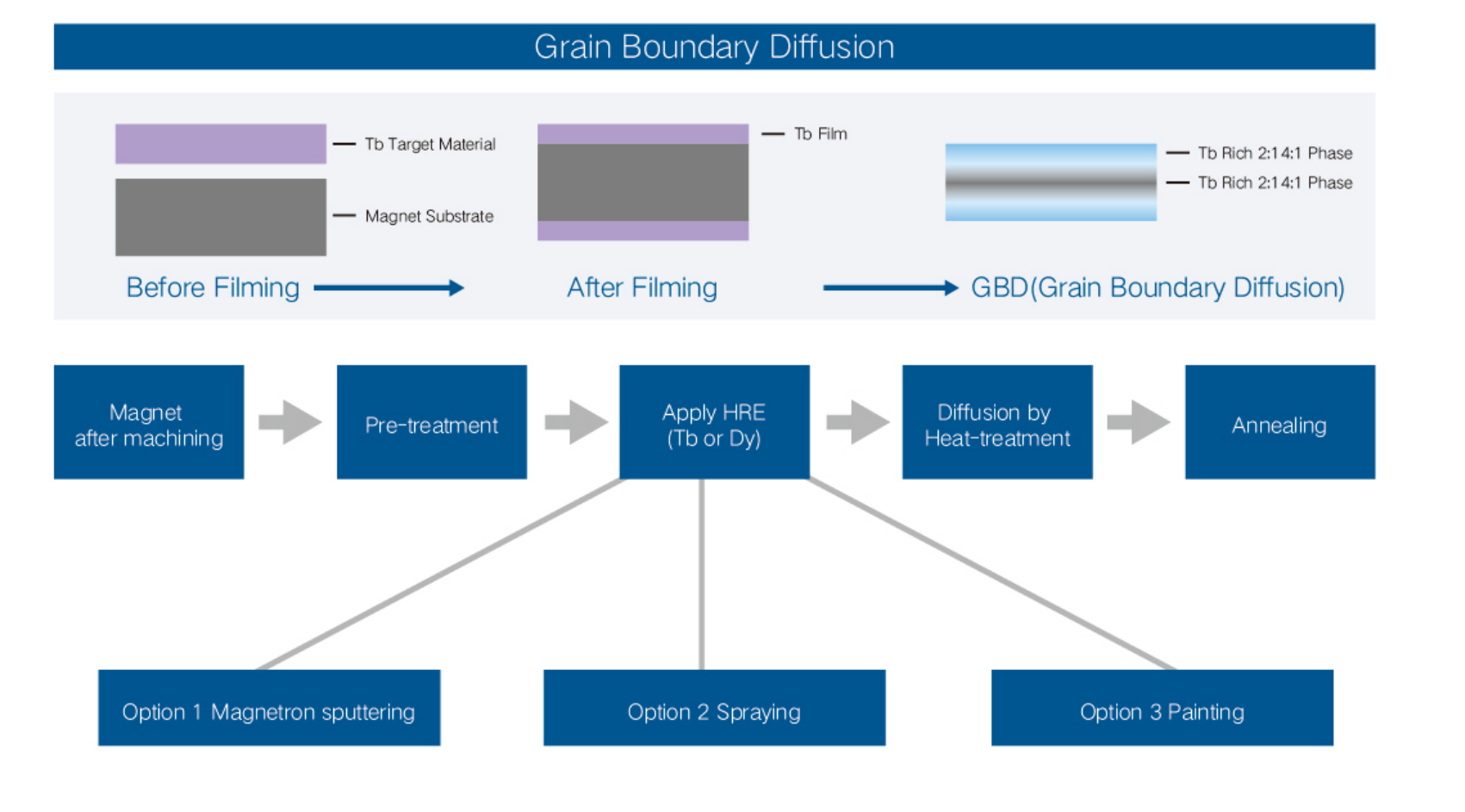

Grain Boundary Diffusion

Surface Treatment

Inspect

Package

Transport

| Magnetic properties of N series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N55 | 1470-1530 (14.7-15.3) | ≥860(≥10.8) | ≥876(≥11) | 414-438 (52-56) | 70 |

| 2 | N52 | 1430-1480 (14.3-14.8) | ≥860(≥10.8) | ≥876(≥11) | 398-422 (50-53) | 70 |

| 3 | N50 | 1400-1450 (14.0-14.5) | ≥860(≥10.8) | ≥960(≥12) | 382-406 (48-51) | 70 |

| 4 | N48 | 1380-1420 (13.8-14.2) | ≥836(≥10.5) | ≥900(≥11) | 366-390 (46-49) | 80 |

| 5 | N45 | 1320-1380 (13.2-13.8) | ≥876(≥11.0) | ≥960(≥12) | 342-366 (43-46) | 80 |

| 6 | N42 | 1280-1320 (12.8-13.2) | ≥923(≥11.6) | ≥960(≥12) | 318-342 (40-43) | 80 |

| 7 | N40 | 1250-1280 (12.5-12.8) | ≥923(≥11.6) | ≥960(≥12) | 302-326 (38-41) | 80 |

| 8 | N38 | 1220-1250 (12.2-12.5) | ≥899(≥11.3) | ≥960(≥12) | 287-310 (36-39) | 80 |

| 9 | N35 | 1180-1220 (11.8-12.2) | ≥868(≥10.9) | ≥960(≥12) | 263-287 (33-36) | 80 |

| 10 | N33 | 1130-1180 (11.3-118) | ≥836(≥10.5) | ≥960(≥12) | 247-270 (31-34) | 80 |

| 11 | N30 | 1080-1130 (10.8-11.3) | ≥796(≥10) | ≥960(≥12) | 223-247 (28-31) | 80 |

| Magnetic properties of M series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N55M | 1470-1530 (14.7-15.3) | ≥1035(≥13.0) | ≥1114(≥14) | 414-438 (52-56) | 100 |

| 2 | N52M | 1430-1480 (14.3-14.8) | ≥1035(≥13.0) | ≥1114(≥14) | 398-414 (50-52) | 100 |

| 3 | N50M | 1400-1450 (14.0-14.5) | ≥1035(≥13.0) | ≥1114(≥14) | 382-406 (48-51) | 100 |

| 4 | N48M | 1380-1430 (13.7-14.3) | ≥1027(≥12.9) | ≥1114(≥14) | 366-390 (46-49) | 100 |

| 5 | N45M | 1330-1380 (13.2-13.8) | ≥995(≥12.5) | ≥1114(≥14) | 342-366 (43-46) | 100 |

| 6 | N42M | 1280-1330 (12.8-13.2) | ≥955(≥12.0) | ≥1114(≥14) | 318-342 (40-43) | 100 |

| 7 | N40M | 1250-1280 (12.5-12.8) | ≥923(≥11.6) | ≥1114(≥14) | 302-326 (38-41) | 100 |

| 8 | N38M | 1220-1250 (12.2-12.5) | ≥899(≥11.3) | ≥1114(≥14) | 287-310 (36-39) | 100 |

| 9 | N35M | 1180-1220 (11.8-12.2) | ≥868(≥10.9) | ≥1114(≥14) | 263-287 (33-36) | 100 |

| 10 | N33M | 1130-1180 (11.3-11.8) | ≥836(≥10.5) | ≥1114(≥14) | 247-270 (31-34) | 100 |

| 11 | N30M | 1080-1130 (10.8-11.3) | ≥796(≥10.0) | ≥1114(≥14) | 223-247 (28-31) | 100 |

| Magnetic properties of H series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N54H | 1450-1530 (14.5-15.3) | ≥1035(≥13.0) | ≥1274(≥16) | 414-438 (52-55) | 120 |

| 2 | N52H | 1430-1480 (14.3-14.8) | ≥1035(≥13.0) | ≥1274(≥16) | 398-414 (50-52) | 120 |

| 3 | N50H | 1400-1450 (14.0-14.5) | ≥1035( ≥13.0) | ≥1274(≥16) | 382-406 (48-51) | 120 |

| 4 | N48H | 1370-1430 (13.7-14.3) | ≥1035(≥13.0) | ≥1274(≥16) | 366-390 (46-49) | 120 |

| 5 | N46H | 1330-1380 (13.3-13.8) | ≥1018(≥12.8) | ≥1274(≥16) | 350-374 (44-47) | 120 |

| 6 | N45H | 1330-1380 (13.3-13.8) | ≥1010(≥12.7) | ≥1353(≥17) | 342-366 (43-46) | 120 |

| 7 | N44H | 1310-1360 (13.1-13.6) | ≥1003(≥12.6) | ≥1353(≥17) | 326-358 (42-45) | 120 |

| 8 | N42H | 1280-1330 (12.8-13.3) | ≥995(≥12.5) | ≥1353(≥17) | 318-342 (40-43) | 120 |

| 9 | N40H | 1250-1280 (12.5-12.8) | ≥940(≥11.8) | ≥1353(≥ 17) | 302-326 (38-41) | 120 |

| 10 | N38H | 1220-1250 (12.2-12.5) | ≥899(≥11.3) | ≥1353(≥17) | 287-310 (36-39) | 120 |

| 11 | N35H | 1180-1220 (11.8-12.2) | ≥ 876(≥11.0) | ≥1353(≥ 17) | 263-287 (33-36) | 120 |

| 12 | N33H | 1130-1180 (11.3-11.8) | ≥844(≥10.6) | ≥1353(≥ 17) | 247-271 (31-34) | 120 |

| 13 | N30H | 1080-1130 (10.8-11.3) | ≥812(≥10.2) | ≥1353(≥17) | 223-247 (28-31) | 120 |

| Magnetic properties of SH series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N52SH | 1430-1450 (14.3-14.5) | ≥1050(≥13.2) | ≥1600(≥ 20) | 406-430 (51-54) | 150 |

| 2 | N5OSH | 1400-1430 (14.0-14.3) | ≥1035(≥13.0) | ≥1600(≥20) | 390-406 (49-51) | 150 |

| 3 | N48SH | 1370-1430 (13.7-14.3) | ≥1003(≥12.6) | ≥1600(≥20) | 366-390 (46-49) | 150 |

| 4 | N45SH | 1320-1380 (13.2-13.8) | ≥1003(≥12.6) | ≥1600(≥20) | 342-366 (43-46) | 150 |

| 5 | N44SH | 1310-1350 (13.1-13.5) | ≥1003(≥12.6) | ≥1600(≥20) | 334-358 (42-45) | 150 |

| 6 | N42SH | 1280-1320 (12.8-13.2) | ≥995(≥12.5) | ≥1600(≥20) | 318-342 (40-43) | 150 |

| 7 | N40SH | 1250-1280 (12.5-12.8) | ≥947(≥11.9) | ≥1600(≥ 20) | 302-326 (38-41) | 150 |

| 8 | N38SH | 1220-1250 (12.2-12.5) | ≥931(≥11.7) | ≥1600(≥20) | 287-310 (36-39) | 150 |

| 9 | N35SH | 1180-1220 (11.8-12.2) | ≥907(≥11.4) | ≥1600(≥20) | 263-287 (33-36) | 150 |

| 10 | N33SH | 1130-1180 (11.3-11.8) | ≥844(≥10.6) | ≥1600(≥20) | 247-271 (31-34) | 150 |

| 11 | N30SH | 1080-1130 (10.8-11.3) | ≥804(≥10.01) | ≥1600(≥ 20) | 223-247 (28-31) | 150 |

| Magnetic properties of UH series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N45UH | 1310-1350 (13.1-13.5) | ≥1003(≥12.6) | ≥2000(≥25) | 334-358 (42-45) | 180 |

| 2 | N42UH | 1280-1320 (12.8-13.2) | ≥907(≥11.4) | ≥2000(≥25) | 318-342 (40-43) | 180 |

| 3 | N40UH | 1250-1280 (12.5-12.8) | ≥907(≥11.4) | ≥2000(≥25) | 302-326 (38-41) | 180 |

| 4 | N38UH | 1220-1250 (12.2-12.5) | ≥907(≥11.4) | ≥2000(≥25) | 287-310 (36-39) | 180 |

| 5 | N35UH | 1180-1220 (11.8-12.2) | ≥875(≥11.0) | ≥2000(≥25) | 263-287 (33-36) | 180 |

| 6 | N33UH | 1130-1180 (11.3-11.8) | ≥844(≥10.6) | ≥2000(≥25) | 247-271 (31-34) | 180 |

| 7 | N30UH | 1080-1130 (10.8-11.3) | ≥835(≥10.5) | ≥2000(≥25) | 223-247 (28-31) | 180 |

| 8 | N28UH | 1020-1080 (10.2-10.8) | ≥764(≥9.6) | ≥2000(≥25) | 207-239 (26-30) | 180 |

| Magnetic properties of EH series and AH series magnets | ||||||

| negate | level | magnetic properties | maximum operating temperature TW(oC) | |||

| remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | Intrinsic coercivity,H | maximum energy product, (BH) max kJ/m3or MGOe | |||

| 1 | N42EH | 1280-1310 (12.8-13.1) | ≥907(≥11.4) | ≥2388(≥30) | 320-340 (38-41) | 200 |

| 2 | N40EH | 1250-1280 (12.5-12.8) | ≥907(≥11.4) | ≥ 2388(≥30) | 302-326 (38-41) | 200 |

| 3 | N38EH | 1220-1250 (12.2-12.5) | ≥907(≥11.4) | ≥2388(≥30) | 287-310 (36-39) | 200 |

| 4 | N35EH | 1180-1220 (11.8-12.2) | ≥876(≥11.0) | ≥2388(≥30) | 263-287 (33-36) | 200 |

| 5 | N33EH | 1130-1180 (11.3-11.8) | ≥812(≥10.2) | ≥2388(≥30) | 247-271 (31-34) | 200 |

| 6 | N30EH | 1080-1130 (10.8-11.3) | ≥812(≥10.2) | ≥2388(≥30) | 223-247 (28-31) | 200 |

| 7 | N28EH | 1040-1080 (10.4-10.8) | ≥780(≥9.8) | ≥2400(≥30) | 207-231 (26-29) | 200 |

| 8 | N38AH | 1220-1250 (12.2-12.5) | ≥907(≥11.4) | ≥2706(≥34) | 287-310 (36-39) | 240 |

| 9 | N35AH | 1180-1220 (11.8-12.2) | ≥812(≥10.2) | ≥2785(≥35) | 263-287 (33-36) | 240 |

| 10 | N33AH | 1130-1180 (11.3-11.8) | ≥812(≥10.2) | ≥2785(≥35) | 247-271 (31-34) | 240 |

| 11 | N30AH | 1080-1130 (10.8-11.3) | ≥812(≥10.2) | ≥2785(≥35) | 223-247 (28-31) | 240 |

Notes

The above data was developed with reference to the Chinese national standard GB/T 3560

Testing method according to the magnetic material testing standard GB/T3217

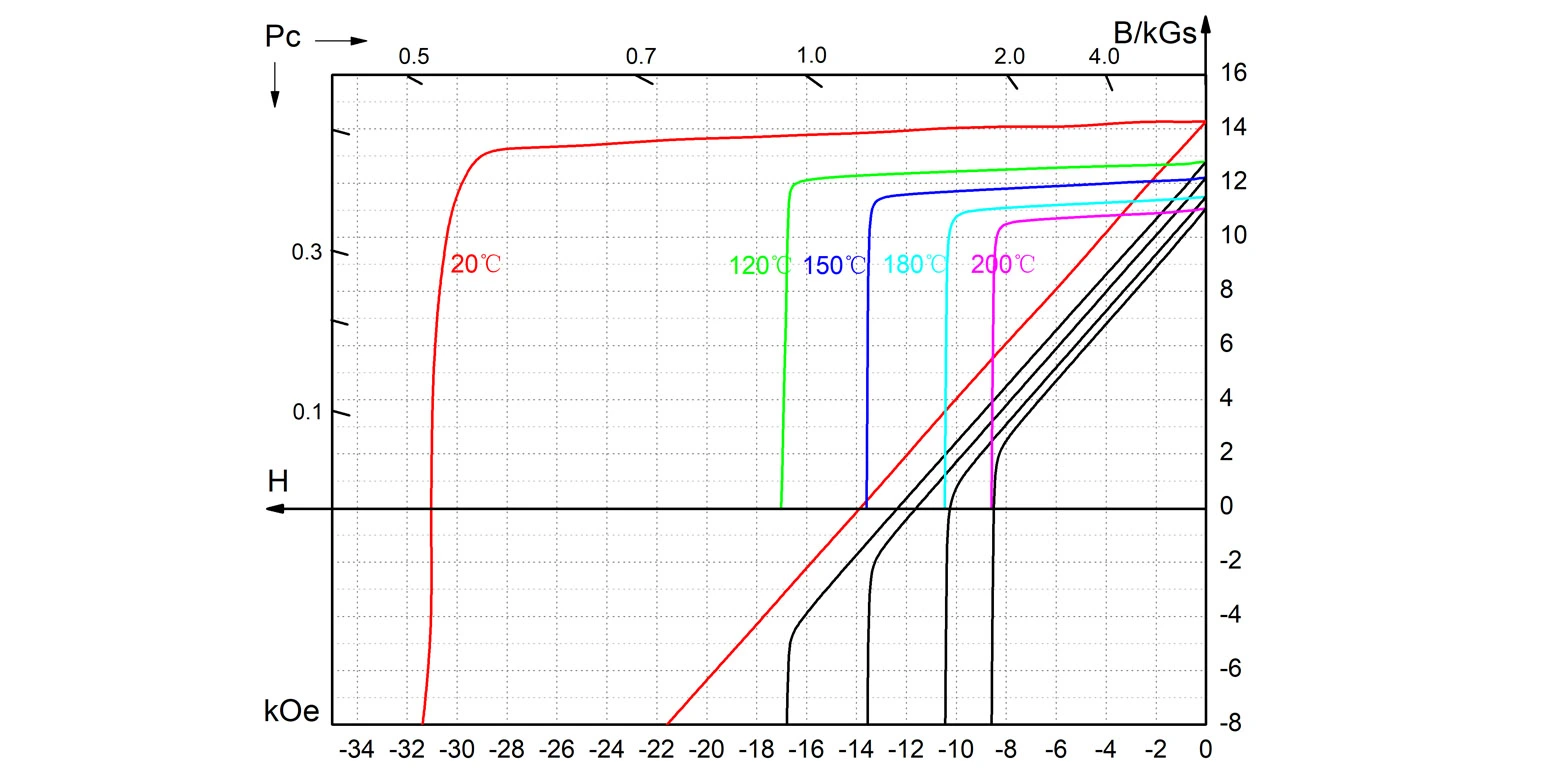

For high temperature characteristics, specifications should be determined according to customer requirements.

Conversion between SI and CGS: 1t = 10kGs,1 koe = 79.6ka/m,1 mgoe = 7.96kj/m3

The maximum operating temperature refers to the irreversible magnetic flux loss during an open circuit test; le; 5%, And the temperature point when the PC value of the magnet is L/D=0.7.

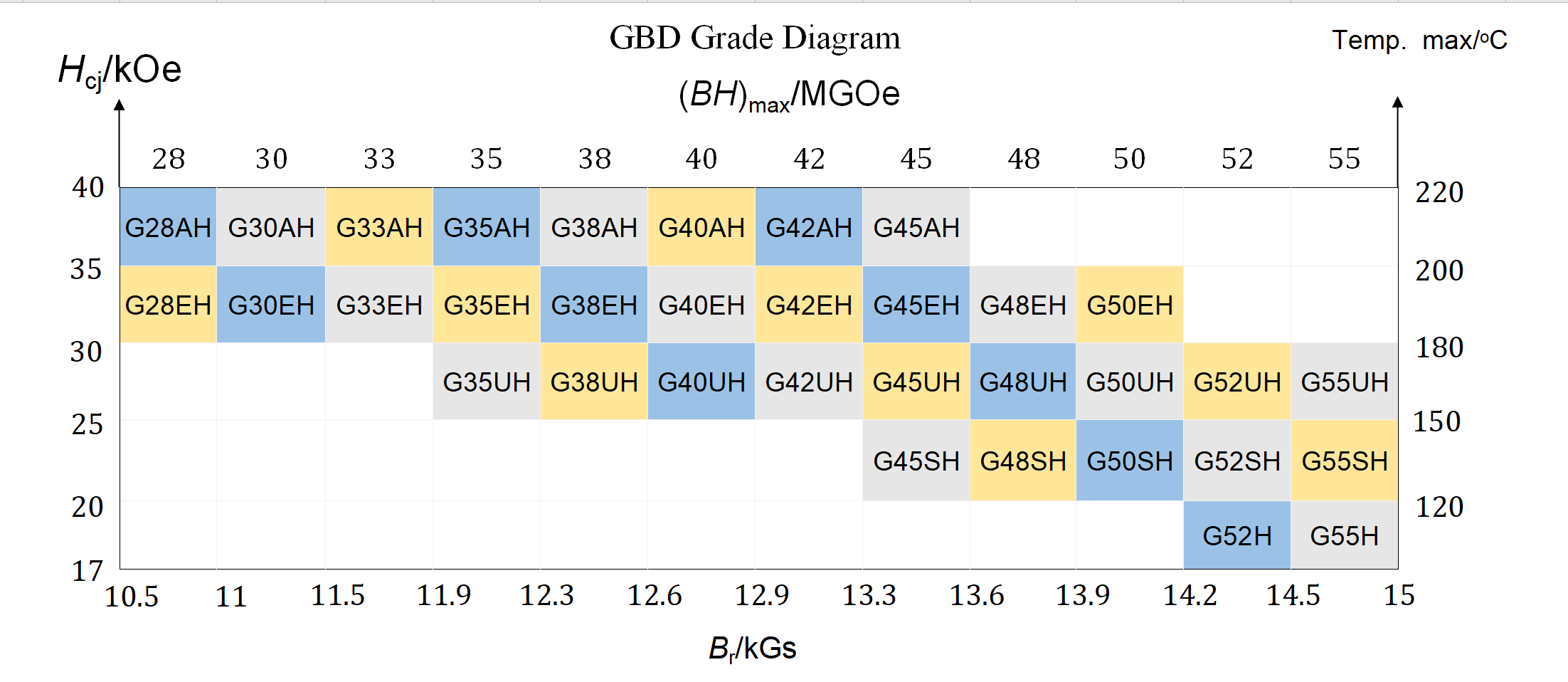

GBDperformance | |||||

| level | remanence,Br mT or kGs | coercive force、Hcb kA/m or kOe | intrinsic coercivity,H cJ kA/m or kOe | maximum energy product, (BH) maximum kJ/m3 or MGOe | Maximum working temperature TW(°C) |

| G55H | 1440-1480(14.4-14.8) | ≥ 1061(≥ 13.3) | ≥ 1353(≥ 17) | 398-422 (53-56) | 120 |

| G52H | 1410-1470(14.1-14.7) | ≥ 1050(≥ 13.2) | ≥ 1353(≥ 17) | 398-422 (50-53) | 120 |

| G55SH | 1440-1480(14.4-14.8) | ≥ 1050(≥ 13.3) | ≥ 1592(≥ 20) | 398-422 (53-56) | 150 |

| G52SH | 1430-1450(14.3-14.5) | ≥ 1050(≥ 13.2) | ≥ 1592(≥ 20) | 406-430 (51-54) | 150 |

| G5OSH | 1400-1450(14.0-14.5) | ≥ 1035(≥ 13.0) | ≥ 1592(≥ 20) | 382-406 (48-51) | 150 |

| G48SH | 1370-1430(13.7-14.3) | ≥ 1035(≥ 13.0) | ≥ 1592(≥ 20) | 366-390 (46-49) | 150 |

| G45SH | 1320-1370(13.2-13.7) | ≥ 1003(≥ 12.6) | ≥ 1592(≥ 20) | 342-366 (43-46) | 150 |

| G52UH | 1410-1470(14.1-14.6) | ≥ 1050(≥ 13.2) | ≥ 1990(≥ 25) | 398-422 (50-53) | 180 |

| G50UH | 1400-1450(14.0-14.5) | ≥ 1035(≥ 13.0) | ≥ 1990(≥ 25) | 382-406 (48-51) | 180 |

| G48UH | 1370-1430(13.7-14.3) | ≥ 1035(≥ 13.0) | ≥ 1990(≥ 25) | 366-390 (46-49) | 180 |

| G45UH | 1300-1360(13.0-13.6) | ≥ 1003(≥ 12.6) | ≥ 1990(≥ 25) | 342-366 (43-46) | 180 |

| G42UH | 1280-1340(12.8-13.4) | ≥ 907(≥ 11.4) | ≥ 1990(≥ 25) | 318-342 (40-43) | 180 |

| G40UH | 1260-1310(12.6-13.1) | ≥ 907(≥ 11.4) | ≥ 1990(≥ 25) | 302-326 (38-41) | 180 |

| G50EH | 1400-1450(14.0-14.5) | ≥ 1035(≥ 13.0) | ≥ 2388(≥ 30) | 382-406 (48-51) | 200 |

| G48EH | 1370-1430(13.7-14.3) | ≥ 1035(≥ 13.0) | ≥ 2388(≥ 30) | 366-390 (46-49) | 200 |

| G45EH | 1300-1360(13.0-13.6) | ≥ 1003(≥ 12.6) | ≥ 2388 (≥ 30) | 342-366 (43-46) | 200 |

| G42EH | 1280-1320(12.8-13.2) | ≥ 907(≥ 11.4) | ≥ 2388 (≥ 30) | 318-342 (40-43) | 200 |

| G40EH | 1260-1310(12.6-13.1) | ≥ 907(≥ 11。4) | ≥ 2388 (≥ 30) | 302-326 (38-41) | 200 |

| G38EH | 1220-1270(12.2-12.7) | ≥ 907(≥ 11.4) | ≥ 2388 (≥ 30) | 287-310 (36-39) | 200 |

| G45AH | 1300-1360(13.0-13.6) | ≥ 1003(≥ 12.6) | ≥ 2786(≥ 35) | 342-366 (43-46) | 220 |

| G42AH | 1280-1340(12.8-13.4) | ≥ 907(≥ 11.4) | ≥ 2786(≥ 35) | 318-342 (40-43) | 220 |

| G40AH | 1260-1310(12.6-13.1) | ≥ 907(≥ 11.4) | ≥ 2786(≥ 35) | 302-326 (38-41) | 220 |

| G38AH | 1220-1250(12.2-12.5) | ≥ 907(≥ 11.4) | ≥ 2786(≥ 35) | 287-310 (36-39) | 220 |

| G35AH | 1160-1230(11.6-12.3) | ≥ 812(≥ 10.2) | ≥ 2786(≥ 35) | 263-287 (33-36) | 220 |

| Shape Type | Picture | Dimenion | Recommend size/mm | Maximum value size/mm |

| Piece |

| L | ≤ 180 | ≤ 220 |

| W | ≤ 120 | ≤ 150 | ||

| T | ≤ 60 | ≤ 80 | ||

| Cylinder |

| D | ≤ 150 | ≤ 220 |

| T | ≤ 60 | ≤ 80 | ||

| Ring |

| D | ≤ 120 | ≤ 160 |

| d | ≤ 80 | ≤ 100 | ||

| T | ≤ 45 | ≤ 65 | ||

| Segmenting |

| L | ≤ 180 | ≤ 220 |

| W | ≤ 120 | ≤ 150 | ||

| T | ≤ 60 | ≤ 80 | ||

| a | 0-180 °C | |||

Weight limit for each item: "Recommended size" ≤ 5kg; Maximum size ≤ 10kg

The maximum size can be related to the grade of the magnet.

Type | Coating Type | Color | Thickness/um | SST/h | PCT/h | Salt immersion test | Working temp./℃ |

Metal coating | Blue Zn | Blue/White | 5-10 | ≥48 | ≥48 | N/A | <160 |

Color Zn | Multiple colors | 5-10 | ≥72 | ≥72 | N/A | <160 | |

NiCuNi | Silver white | 10-30 | ≥72 | ≥96 | N/A | <200 | |

Al | Silver white | 5-25 | ≥96 | ≥240 | N/A | <390 | |

Organic coating | Epoxy (electro) | Black/Grey | 10-30 | ≥480 | ≥96 | N/A | <180 |

Epoxy (spray) | Black/Grey | 10-30 | ≥480 | ≥96 | N/A | <180 | |

Multi-layer coating | NiCuNi+coating | Black/Grey | 15-45 | ≥720 | ≥168 | N/A | <180 |

Inorganic coating | Phosphate/ Passivated | Grey | <2 | N/A | N/A | 1H | <250 |

Bluing | Blue | <2 | N/A | N/A | 2H | <250 |

The above data represent the best performance. The actual specification is to be adjusted according to variable product size and shape.

Muli-layer coatings is a combination of different type of coatings. It' S color, thickness and working temperature may vary from different combinations.

Test condition of PCT: 121°C, 100% humidity, 2 atms

Test condition of HAST: 132"C, 95% humidity, 2.7 atms. HAST is to evaluate the weight loss of magnet after testing, the lower the better.